Road Network Operations

& Intelligent Transport Systems

A guide for practitioners!

Road Network Operations

& Intelligent Transport Systems

A guide for practitioners!

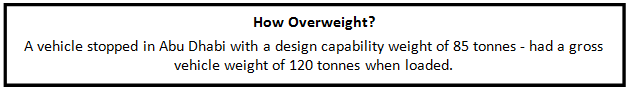

The enforcement of weight limitations is one of the key challenges in ensuring safe movement of freight by heavy goods vehicles. Vehicles loaded beyond their design capabilities pose a safety hazard to the public and other road users destabilising braking systems and suspension.

Inappropriately configured and overloaded vehicles also cause greater damage to the road surface and structures (such as fatigue on bridges) increasing the maintenance costs of road transport authorities. ITS offers a range of options for ensuring that regulatory requirements are adhered to – and can help increase the accuracy of high speed Weigh-in-Motion systems.

The acquisition of vehicle loading information facilitates enforcement of loading regulations and optimisation of maintenance operations.

Weight checks by public authorities traditionally involve weighing heavy vehicles on static scales, low-speed weigh-in-motion scales, at weighing stations or under portable pads placed underneath the vehicle’s tyres. They are expensive to operate because of the staff resource required. Consequently they tend to be operated for a few hours at any one time – and so only ever weigh a small proportion of potentially over-laden traffic – as well as being easy to avoid.

Improvements in technology have fostered the widespread adoption of Weigh-in-Motion (WIM) sensors across road networks - especially in Europe. Germany, Italy, Spain, Portugal, Switzerland and the United Kingdom have invested in many installations – but France outstrips them all in numbers of WIMs installed. WIM systems are generally divided into three varieties:

The future for WIM will involve improving the precision of sensors so they can be used remotely for enforcement of weight regulations in combination with some method of vehicle owner or operator identification - such as ANPR. In the UK ANPR combined with low-speed WIM or weighbridge is used to detect overweight vehicles so they can be checked by officials. (See Case Study ‘VOSA WiMs (United Kingdom))

There is the possibility of weighing some vehicles without the need for road sensor infrastructure. These are usually installed by operators who may wish to determine that their vehicles are not overloaded or may want to know how much they are carrying (for example, a tipper truck carrying gravel).

Systems can usually be broken down into two varieties - those that weigh the load and those that weigh the entire vehicle. Systems which weigh the load use load cells attached to body mounts. Systems which weigh vehicles, measure stress levels on key parts of the chassis to evaluate full vehicle weight. These systems help operators avoid unknowingly allowing overweight vehicles to be driven, whilst also ensuring that they can maximise legal payloads.

The most important aspect, when dealing with weigh stations, is to ensure that they are regularly and correctly calibrated. Mobile stations offer flexibility and prevents hauliers or operators from routing around weigh stations. It is important to keep a record of offenders, and, wherever possible, link this to other systems such as those which check credentials.