The prime objective of commercial operations is to move goods to the place at the time at a price that is competitive and yet profitable. The drive for maximising profit may tempt some vehicle operators to break the rules (on driver hours or lorry weights) to carry more freight at a lower cost. This potentially endangers both the environment and society as a whole as well as individual drivers and members of the public. The vision of a safe, secure and well-managed transport industry requires enforcement on three broad fronts which ensure that:

However, stopping vehicles to verify compliance is time-consuming and causes economic loss through delayed journeys and deliveries. ITS provides solutions to better target those more likely to breach regulations freeing up law enforcement resources and permitting law-abiding drivers and operators to continue uninterrupted.

This topic covers:

A safe, secure and well-managed network is of importance to all parties involved with freight. It is particularly important to traffic police, employers representatives and trade associations, transport authorities, operators and shippers. As trade becomes increasingly global, bodies such as TISPOL (European Traffic Police Network) provide an umbrella for sharing information between enforcement authorities on dangerous operators and best practice for enforcement procedures.

Security is a major issue in international trade. As globalisation continues apace, trade increasingly takes place across international borders. It is a challenge to ensure that trade is safe, legal and efficient. A number of initiatives seek to improve the speed at which freight can be cleared through border controls without compromising the integrity of loads and the ability to inspect suspect loads.

The Next Generation Single Window concept has been developed by the United Nations Centre for Trade Facilitation and Electronic Business (UN/CEFACT), the World Customs Organisation (WCO) and other bodies. It is a facility that allows parties involved in trade and transport to provide standardised information and documents through a single entry point to fulfil all regulatory requirements for import, export and transit. If information is electronic, individual data elements need only be submitted once. The United States’ eManifest system deployed along its land borders with Canada and Mexico is an example.

Storage of multiple data (such as crew/driver, load) in a single place offers many benefits. ANPR cameras van, for example, trigger the collection of data as trucks approach a border so that the correct manifest can be loaded ready for customs inspection. This speeds up inspections allowing more time for the more stringent secondary checks on those operators, drivers, trucks or cargo which have a history of customs infringements. It also offers the possibility of pooling data for planning and enforcement.

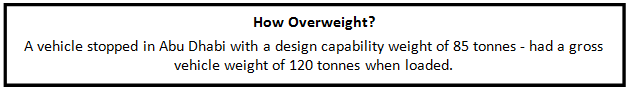

The enforcement of weight limitations is one of the key challenges in ensuring safe movement of freight by heavy goods vehicles. Vehicles loaded beyond their design capabilities pose a safety hazard to the public and other road users destabilising braking systems and suspension.

Inappropriately configured and overloaded vehicles also cause greater damage to the road surface and structures (such as fatigue on bridges) increasing the maintenance costs of road transport authorities. ITS offers a range of options for ensuring that regulatory requirements are adhered to – and can help increase the accuracy of high speed Weigh-in-Motion systems.

The acquisition of vehicle loading information facilitates enforcement of loading regulations and optimisation of maintenance operations.

Weight checks by public authorities traditionally involve weighing heavy vehicles on static scales, low-speed weigh-in-motion scales, at weighing stations or under portable pads placed underneath the vehicle’s tyres. They are expensive to operate because of the staff resource required. Consequently they tend to be operated for a few hours at any one time – and so only ever weigh a small proportion of potentially over-laden traffic – as well as being easy to avoid.

Improvements in technology have fostered the widespread adoption of Weigh-in-Motion (WIM) sensors across road networks - especially in Europe. Germany, Italy, Spain, Portugal, Switzerland and the United Kingdom have invested in many installations – but France outstrips them all in numbers of WIMs installed. WIM systems are generally divided into three varieties:

The future for WIM will involve improving the precision of sensors so they can be used remotely for enforcement of weight regulations in combination with some method of vehicle owner or operator identification - such as ANPR. In the UK ANPR combined with low-speed WIM or weighbridge is used to detect overweight vehicles so they can be checked by officials. (See Case Study ‘VOSA WiMs (United Kingdom))

There is the possibility of weighing some vehicles without the need for road sensor infrastructure. These are usually installed by operators who may wish to determine that their vehicles are not overloaded or may want to know how much they are carrying (for example, a tipper truck carrying gravel).

Systems can usually be broken down into two varieties - those that weigh the load and those that weigh the entire vehicle. Systems which weigh the load use load cells attached to body mounts. Systems which weigh vehicles, measure stress levels on key parts of the chassis to evaluate full vehicle weight. These systems help operators avoid unknowingly allowing overweight vehicles to be driven, whilst also ensuring that they can maximise legal payloads.

The most important aspect, when dealing with weigh stations, is to ensure that they are regularly and correctly calibrated. Mobile stations offer flexibility and prevents hauliers or operators from routing around weigh stations. It is important to keep a record of offenders, and, wherever possible, link this to other systems such as those which check credentials.

A well-managed system requires that all vehicles, drivers and operators have the correct licences, training and certificates. This is becoming significantly easier because of the combination of e-documents which can be accessed remotely using cloud based computing. Roadside enforcement officials can access all the very latest documents relating to a vehicle and deal with any infringement of regulations immediately. This capability mean that relevant information can be accessed at spot checks – for example information on roadworthiness tests (the MOT in UK, ITV in Spain, APK in the Netherlands or TÜV in Germany).

The easy availability of ITS technologies such as those described reinforces the importance of operators and drivers “playing by the rules”. Those who cut corners by illegally cutting costs distort competition and undermine legitimate operations to the detriment of the entire freight logistics market.

Building on the work from eManifest and other sources (such as safety information exchange, border clearance and weight screening) it has become possible for law enforcement officials within some countries to have access to large amounts of data at the roadside. This facilitates targeted enforcement. Vehicles from operators with poor records of compliance can be targeted, whilst those from firms with better records can be to continue without delay to their destination. In the UK, an Operator Compliance Risk Score (OCRS) system is used whereby operators ranked as low risk (“green”) are less likely to have their vehicles stopped than vehicles from operators ranked “red”. There is also an “amber” score in the middle. This score is created through a combination of roadworthiness checks and traffic enforcement compliance (drivers’ hours, weighing checks and the outcome of roadside inspections). Any discrepancies with the details recorded and accessible from the cloud - for operators, drivers or vehicles - can be checked and acted upon.

The names of credential compliance systems vary from country to country (for example, TAN21 in the United Kingdom, CVISN in the United States) but operate on a similar basis. The authorities for operators, vehicle licensing and enforcement can all upload the relevant information about the vehicle and driver where it is available in a central system that can access these databases. The system itself is accessed by roadside enforcement officials.